Highlight

Successful together – our valantic Team.

Meet the people who bring passion and accountability to driving success at valantic.

Get to know usThe Collaboration Platform for Supply Chain Management

Better collaboration along complex, multi-tier supply chains

Planning and controlling your production with the Advanced Planning & Scheduling (APS) software wayRTS (Real Time Simulation) achieves a high degree of transparency and adherence to deadlines. However, in complex multi-tier value chains, there are factors that are not part of the company itself. Planning-relevant information from suppliers is not available in due time and must be obtained with considerable effort in some cases. It would also be desirable to keep customers up-to-date on progress and get easy feedback with no extra effort. In order to further optimize supply chain management, external partners must be involved. And that’s exactly what the wayCloud platform offers.

Incorporate customers, control suppliers

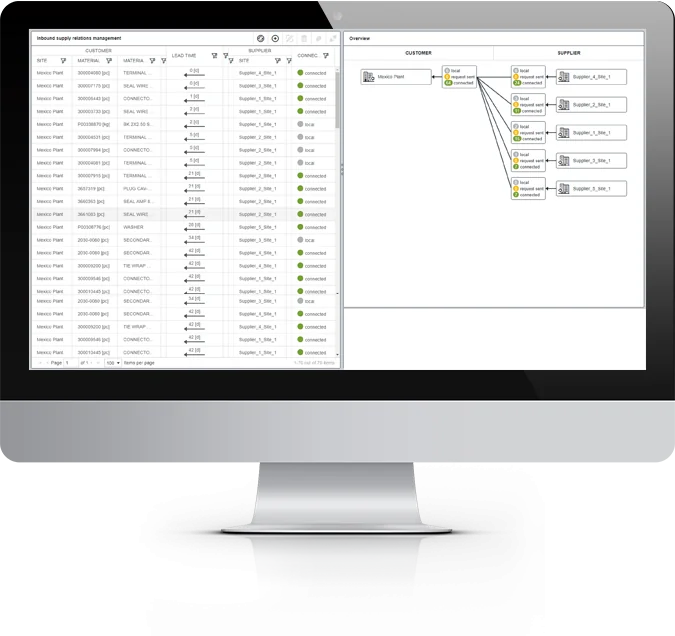

The software-as-a-service (SaaS) platform wayCloud allows you to connect as many customers and suppliers as you like with the apps tailored to the specific use cases. It provides partners with secure, precisely defined insight into their own planning results and serves as a convenient communication platform for coordination. The result: Any information is shared easily and securely with all partners involved in the process. The transparency gained this way increases the predictability of logistics processes. The wayCloud Platform Apps are ideal for demand and capacity matching, task management, communicating project and order progress, and calculating greenhouse gas emissions along the supply chain. Collaboration on the platform increases delivery reliability and delivery capability, potential supply bottlenecks can be avoided at an early stage, and emission reduction potential can be identified. The various functions can be selected and booked as individual apps. You only pay and share with your partners what you actually use.

wayCloud Platform – The Collaboration Platform for Supply Chain Management (SCM)

Include customers and manage suppliers. Read here how you can successfully collaborate along complex, multi-level supply chains with the wayCloud Platform and achieve transparency and planning security in SCM.

Typical use cases

Automated integration of contract manufacturers into the value creation process

wayCloud Platform offers a simple way to integrate contract manufacturers into planning processes with the Collaboration Lists app. The integration allows the quantities, production sequence, and specific prioritization of critical orders to be transferred to the external partner without any effort. Thanks to the bi-directional communication, feedback, deviations, and changes can be communicated as quickly as possible.

Share wayPRO and Microsoft Project project plans with project partners via the cloud

In project-driven business, for example in plant engineering, there are many dependencies, because the customer must have conditions for assembly, for example. The Projects app provides a convenient way to share project plans and communicate activities and milestones.

Tasks for fine-tuning in project plans can be created and edited directly in the app according to the process steps. The wayCloud platform has a standard interface to wayPRO, but also allows a simple manual MS Project upload.

Align requirements and delivery capacities

Matching your own demand or delivery capacities with those of suppliers is a complex task. The easier it is to exchange information, the better this will go. The CCM (Connected Chain Manager) app of the way-Cloud Platform facilitates communication among partners along the multi-tier supply chain. Demand forecasts are shared and compared with actual quantities. Delivery capacity ranges, including upper and lower limits, are determined over the months. Demand fluctuations can be analyzed and warnings issued. Order promising enables easy communication of changes to orders and call-offs. Traceability of status changes and histories in the procurement process increases transparency for all parties involved. The transparency of stock ranges ensures the supply situation and increases the response time. This includes transit tracking and use of stock range KPIs to quickly identify critical materials. The graphical representation of over- and understocks facilitates the optimization of inventories. Here, valantic relies on its cooperation with Prewave, an AI (artificial intelligence) start-up that offers a global AI risk management platform. This enables risk information to be integrated and comprehensive risk monitoring and alerting to be set up.

Compiling a carbon footprint and identifying reduction potentials

The Corporate Carbon Footprint (CCF), also called climate balance, describes the sum of all direct and indirect greenhouse gas emissions of a company. With the CCF tool of the wayCloud Platform, you can calculate your carbon footprint or create your carbon footprint in an uncomplicated and standardized way in order to identify individual levers and derive suitable reduction measures. You can create your CCF in just two steps: First, record your operational activity data and then link it to emission values that you have stored yourself or that are provided by an external database. In addition to a technical solution, we are also happy to support you with expert advice on the subject of sustainability and CO2 transparency. The development of holistic measures is always in the foreground, in that we always consider economic efficiency in addition to ecological benefits.

Advantages for supply chain managers at a glance

Share views and lists from any waySuite modules and installations (cloud, on-premise) with customers and suppliers

Central communication with optional data exchange, topics requiring coordination are simply added as a "task"

Functions can be used as individual apps

Access can be controlled by roles

Encrypted communication, independently verified IT security

Browser-based user interface, access without installation; email notification

Ready-to-use right away, low usage-related costs

TISAX (L3), ISO-27001, and ISO-9001 certified vendor valantic

Microsoft Azure Hosting in Western Europe

Collaboration with the planning process in mind

The wayCloud Platform improves collaboration with suppliers and customers. The cloud service is a convenient way to clarify open questions directly using the data from the planning software and, if necessary, additional documents. Media breaks and duplicate data storage are further reduced in the interest of digital transformation.

The wayCloud Platform for highly complex statistical analyses

In addition to providing applications for collaboration, valantic leverages the flexibility and scalability of the wayCloud platform to provide additional capabilities with large computation requirements. Users can take advantage of these as needed without having to keep the corresponding IT capacities available.

DDO app (MRP data optimization / wayDDO)

With the wayDDO app provided via the wayCloud platform, the wayRTS user can exploit state-of-the-art algorithms to automate and optimize scheduling data. Historical data from the ERP as well as information from the wayRTS material master form the basis of the automatic evaluation.

wayDDO helps you

Optimize production lot sizes based on data from past periods

Perform ABC/XYZ classifications automatically

Automatically set disposition parameters based on classifications

Adjust the level and creation of security stocks

Calculate the optimum reorder level

The recording of the carbon footprint of companies and products.

The availability of the necessary data and the individual parameters are worked out during valantic’s integrated process and IT consulting. The aim is to achieve the best possible demand and inventory management.

Demand Planning app

The Demand Planning Automation app uses state-of-the-art algorithms and AI to provide forecasts for the S&OP process. A challenge for longer-term forecasting is the choice of the appropriate statistical method – wayDDO offers all currently leading technologies.

In valantic’s process and IT consulting, the appropriate calculation methods are defined jointly. From this point on, the ideal forecasting procedure is selected automatically according to the individual reference number, with the best parameterization in each case to minimize the forecast error.

Forecasts can be provided on both the primary and secondary requirements level or on the product group level. wayDDO is a fully integrated solution: The forecast requirements are made available automatically as planned requirements in wayRTS, where they form their own forecast scenarios.

What is calculated this way based on historical data in the cloud fits into an integrated S&OP process with wayRTS. This is where the automatic forecast and sales estimates are coordinated.

By using wayDDO, planners can be sure to always be up-to-date with the statistics software. They will be using the most powerful algorithms for their forecasts and automatically receive high-quality planning bases.

Necessity of supply chain collaboration

In a globalized world, companies are confronted with a continuously increasing number of customers, suppliers and product variants. As a result, the complexity and requirements posed to supply chain management (SCM) are increasing. To maintain competitiveness and profitability, companies are highly dependent on a holistic SCM and the mastery of the associated complexity – internally, across company boundaries and along entire value chains.

If, for example, a supply bottleneck occurs somewhere in the world, the entire supply chain can temporarily come to a standstill or even collapse. Even many minor incidents can bring sand into the gears of supply chains: a traffic jam on the highway, a communication error between plants or a lengthy machine breakdown. Wherever companies are heavily dependent on the smooth running of all processes, there is even the threat of production downtimes and losses of millions in the event of an emergency. IT-supported transparency within the company, let alone across company boundaries to upstream stages of the supply chain, is often inadequate.

valantic’s wayCloud Platform builds bridges: As an innovative, Web-based Software-as-a-Service (SaaS) platform, it connects all partners along the entire supply chain via a simple interface. In doing so, a multitude of relevant information is exchanged, which offers advantages to all parties involved both in critical situations and in regular operations: improved early detection of bottlenecks, fast and aligned coordination in case of a crisis as well as improved planning reliability and efficiency gains ultimately increase the competitiveness of the entire supply chain.

Stock Transparency in Critical Situations

Supply bottlenecks can be visualised immediately using the graphical web interface in valantic’s wayCloud Platform.

Overview of benefits for supply chain managers

Instantly ready for takeoff

No software installation: For the application of the wayCloud Platform an Internet connection and browser are sufficient.

Multi-Level Transparency

The integrated user role concept allows tracking of materials on the supplier level (n-tier).

Data protection

All planning data is saved according to strict data protection directives in Europe.

Easy usability

Plain processes and clear visualizations make the operation of the wayCloud Platform easy.

Attractive pricing model

You only pay what you are actually using: The payment of the wayCloud Platform is a pure pay-per-use concept.

Flexible reporting

User-definable reports make the wayCloud Platform adaptable to your specific needs.

Globalization requires an overview in supply chain management

Globalization and ever-increasing customer requirements put pressure on companies to deliver faster and faster while reducing costs for logistics, storage and transport. The resulting increased complexity in one’s own company and along entire supply chains not only leads to growing intransparency, but also entails coordination efforts and loss of control. This contradicts core objectives of Supply Chain Management (SCM), which aims for supply chains being more efficient, flexible and reactive, while at the same time both costs and efforts should be made transparent and systematically reduced.

In order to achieve these goals nevertheless, innovative and tailor-made IT solutions are required to bring together all relevant information. These solutions must not only focus on the own organization, but on the entire supply chain including all stakeholders – and if possible in real time. Not least for these reasons, the trend is moving more and more towards cloud solutions or web-based Software-as-a-Service platforms such as valantic’s wayCloud Platform.

Immediate reaction in exceptional situations

Many heterogeneous, monolithic IT systems, including SCM and ERP systems, are usually in use along the value chains. In exceptional cases, such as machine failures, immediate notifications and a clear flow of information are essential. This is the only way to quickly analyze and evaluate the existing situation in order to initiate and coordinate suitable countermeasures. What happens if the affected companies and their systems do not communicate with each other at all or only in a very delayed manner?

In such cases, the affected stages of the supply chain are often notified about a potentially critical situation far too late. As a result, attempts are hectically made, usually bilaterally, to obtain the most necessary information by telephone and e-mail in order to initiate emergency measures and to identify a responsible contact person. Unfortunately, a coordinated, efficient counter-reaction usually falls by the wayside.

This is how to create transparency in the supply chain

Direct questions: Do you know your entire supply chain and all the neuralgic processes? Can you easily identify where capacity bottlenecks are imminent and where relevant stocks are kept? Do you know at which points potentials and efficiency gains could be realized?

The first challenge in creating transparency along the value chain is to consolidate all processes, data and figures within your own company in a clear and always up-to-date picture with the help of suitable IT systems. In a second step, especially against the background of increasingly interlinked and globally positioned supply chains, information should be provided, shared and analyzed with all relevant partners using suitable systems – only in this way a holistic view can be guaranteed.

There are only a few systems that, like valantic’s wayCloud Platform, are able to systematically combine all relevant data. This can be done manually via upload (xlsx- or csv-format) or via an automated connection via web interfaces (REST-APIs). In both ways, the structures and material flow in supply chains can be made transparent and analyzed in real time.

As a web-based solution, the wayCloud Platform can be implemented very quickly and provides a reliable analysis of the status quo. Therefore, the software is ideally suited to achieve coordination and solution finding in the value chain in critical supply situations. Joint measures include additional extra tours, temporary shortage management and the deliberate shifting of orders.

Also in regular operations, the wayCloud Platform shows its strengths when it comes to transparency. Regardless of whether in your own company or along the supply chain, capacity bottlenecks, overstocks and demand fluctuations can be detected. Paired with suitable key figures and as a result of the continuous monitoring, early warnings of shortcomings and potentials for efficiency increases are identified. But which key figures are the right ones here?

Flexible evaluation

The efficient reporting functionality of the wayCloud Platform allows a systematic evaluation of actual and historical stock ranges of critical materials. The level of detail of the reports, the selection of materials as well as the visual design can be adjusted in a flexible way. Exporting the reports in standard formats make the sharing of information easy.

After consolidating all data, the structured monitoring of your supply chains with the help of suitable key figures let you keep an overview at all times. In this way, bottlenecks, exceptions and risks can be identified at an early stage. Bad surprises and enormous costs (e.g. due to missing parts or extra tours) can thus be avoided. Especially in critical situations, but also during regular operation, communication is based on a common view and a single point of truth. Dashboards show the current situation in real time at a glance.

valantic’s wayCloud Platform offers the right key figures and reports for almost every application. Cross-tier stock ranges, capacitive utilization, supply bottlenecks and much more. You have the choice: meaningful standard reports? Or a maximum of flexibility? Whatever you decide on: The common data base of the supply chain partners enables real-time visualization and updating of all key figures and thus always a holistic view of the current situation, future developments and analyses of the past. In this way, you gradually increase the competitiveness and performance of your entire supply chain.

Collaborative planning and control of the supply chain

Inter-company transparency is the necessary, robust basis for comprehensive planning and optimal decision-making. Because information is shared directly with partners and work is done using the same database, common efficiency potential can be exploited and the performance of the entire supply chain increased.

Integrated planning and control of your supply chain with the wayCloud Platform guarantees you smooth processes, on-time and on-budget fulfillment of customer requirements, greater efficiency and the potential to significantly reduce your costs. In this context, the wayCloud Platform supports you both in the tactical/operational control of your production as well as in the strategic planning of contingents and capacities. Once customers and suppliers have been integrated, immediate insights into all relevant processes within the supply chain can be shared across all stages. In this way you protect yourself and your partners from wrong or suboptimal decisions and avoidable costs due to inadequate information flows. The definition, coordination and implementation of measures is supported by corresponding collaboration modules directly in the wayCloud Platform.

Multi-level tracking of materials

Stocks of critical materials are managed either centrally or directly by the suppliers at the different levels of the supply chain. The wayCloud Platform enables the distributed tracking of stocks through an efficient user role concept. The measuring of stocks takes place directly in the browser, dedicated interfaces at the suppliers are not necessary.

Application case: Monitoring of incoming deliveries in the short-term area

With the wayCloud Platform, you can map inventory ranges to the material number level for all integrated suppliers with central monitoring. Incoming material flows and inventories in your suppliers’ outgoing goods are allocated according to your requirements (delivery calls or orders). Ranges are generated, which also consider delivery times and defined minimum targets. If the inventory ranges drop below a specified threshold or if there is a supply shortage due to a late arrival, you can see this from the appropriate KPI right away. You can react quickly and communicate proactively with your suppliers. You also know whether there is sufficient inventory at your suppliers and you can request a special transport if necessary. Since the wayCloud Platform also works for all partners, you can create this transparency for your customers and ensure that they generate sufficient inventory ranges with their deliveries and inventories in outgoing goods and can satisfy all needs.

This increases the reliability of material supply along the entire supply chain, makes any bottlenecks visible early on, and improves communication and coordination thanks to common data stocks.

Application case: Medium- and long-term planning of delivery capacities

In order to make not just the short-term supply situation transparent to suppliers and customers, coordinate and monitor it, there is so-called delivery capacity coverage in the wayCloud Platform. You can use this function to work with your partners to synchronize and plan medium- and long-term demands and delivery capacities on the monthly level.

For example, your customer provides you with a preview of his needs on the monthly level and would like to know if you can fulfill these. You can simply transfer delivery capacities on the material number level, also with flexibility upward and downward, to the relevant partner. Both you and your customer see immediately whether delivery capacities are sufficient. Meaningful KPIs and a graphic presentation of the data clarify the situation.

Another example is the planning of your demands with regard to your suppliers. They have already entered delivery capacities for each material and every month in the coming year in wayCloud Platform. Now, you can compare secondary demands, which are calculated using your customers’ demands. Having all this information in one place puts you in a position to plan your delivery calls so that they are appropriate for secondary demands and the promised delivery capacities. You can react early on to deviations and, for example, smooth out demand peaks or request additional delivery capacities.

Application case: Order promising

With the order list, you can communicate orders, delivery calls, and other demands to your suppliers. They can either confirm quantities and dates or communicate new date and quantity proposals. In case of changes or confirmations, the status of the affected data records is updated and written back to your leading ERP system if necessary. This way, you make agreements via a single platform and maintain an overview at all times. Agreements that are otherwise made on the telephone or in other ways are documented centrally on the platform and can be viewed and are transparent for all participants. The order list is therefore an ideal instrument for daily cooperation between customers and suppliers.

Application case: Collaboration via task management (list of open issues)

Use the integrated collaboration possibilities, such as the list of open issues, in order to prioritize, categorize, work through, and document tasks efficiently. You can create various lists for different projects and partners.

The lists can be used internally and in cooperation with your customers and suppliers. Here, as many external partners can be invited to cooperate as you wish, also in the form of guest users if they are not themselves active on the system. Within a few minutes, you can start a new initiative for coordinating and documenting tasks. On request, you will be notified via e-mail of changes to your tasks, so you will remain informed about the current state of affairs at all times. You can incorporate additional information such as files and screenshots easily and monitor progress with appropriate KPIs (e.g. adherence to deadline).

Application case: Multi-level supply chains

Network across several levels with your partners, from parts suppliers to end product manufacturers. Thanks to the exchange of data, such as primary demands, backlog information, and inventories, inventory ranges are calculated considering the entire supply chain. This is how bottleneck components and critical paths can be identified, inventories within the chain optimized, and bull-whip effects prevented.

Application case: Supply chain risk monitoring

Get even more detailed information about your global supply chain and key risks associated with it with Prewave’s risk intelligence platform. Prewave analyzes the supplier information of the network constructed in the wayCloud Platform and creates risk profiles based on historical data. Prewave is therefore able to generate alerts, in many cases even before the event actually occurs. The combination of the material flow mapped in the wayCloud platform and Prewave’s risk information provides a significantly better data basis for making essential supply chain decisions.

FAQs: Your supply chain and the wayCloud Platform

Are you curious about the wayCloud Platform as an effective solution for supply chain transparency and collaboration? In our Frequently Asked Questions (FAQ) you can find out how you can optimize your supply chain management processes in detail with the wayCloud Platform, reduce costs and effort and how quickly the open service platform can be implemented.

Basically, those responsible for supply chain management pursue two goals: On the one hand, they want to make their supply chain increasingly flexible, reactive, resilient and effective. On the other hand, they want to make costs and efforts as transparent as possible in order to systematically reduce them and make supply chains more efficient. Both goals depend on tailor-made, innovative IT solutions such as wayCloud Platform, which focuses not only on the company’s own organization but on the entire supply chain.

For a high level of transparency in the supply chain, users should be able to provide their systems and relevant information quickly and easily on a comprehensive platform. Notification and integration of customers and suppliers must also be very easy and should not involve high costs. As an innovative web platform, the wayCloud Platform offers the necessary flexibility to enable partners to selectively release their data – thus, in addition to shared transparency, data security is guaranteed at all times.

In a transparent supply chain, exceptions and problems can be identified and evaluated immediately using suitable key figures. As soon as, for example, a transit fails to arrive or a machine breaks down at a certain point in the supply chain, the resulting effects can be made visible. Through early, joint definition and coordination of countermeasures (e.g. rescheduling of orders or production lots), serious consequences for the supply situation can in many cases even be completely avoided.

In order to improve the procedures and processes in the supply chain, these must first be known in detail. This also includes the interlinkages and dependencies across company boundaries. This transparency can be achieved through structured data exchange at all levels. Using suitable key figures, joint measures and planning approaches, potentials can then be identified and raised step by step.

End-to-end transparency and a holistic view of the supply chain are the key to reduce expenses at various points. A number of cost drivers can be quantified in this way: Overstocks and shortfalls, avoidable extra tours and incorrect deliveries, capacity reserves and bottlenecks. The special feature of using the wayCloud Platform is that the focus does not have to be solely on your company. In many cases, savings potential can only be identified by taking a holistic view of the supply chain, even across company boundaries.

The key figures best suited for effective supply chain monitoring always depend on the focus and the respective application case. The key figures that have proven to be effective for monitoring the supply chain as a whole and its individual parts include stock range (cumulated across the supply chain), upper/lower stock limits, and corridors for capacities. This allows both bottlenecks and efficiency potential to be reliably identified.

The wayCloud Platform can be used in many different ways and addresses three core application fields:

The wayCloud Platform uses all the advantages of a cloud and web-based application. A central advantage is the fast setup: It usually takes only a few hours from independent online registration to filling the system with your own data, from integrating the first customers and suppliers to creating initial analyses. Our support team will assist you with technical problems. If required, we will also prepare an individual offer for comprehensive support from our supply chain experts.

The wayCloud Platform offers the possibility to connect your systems via open WebAPIs. Of course, this also applies to your customers and suppliers: Here too, data can be integrated automatically. If required, our experts will be happy to provide support and help you set up initial interfaces and data transfer as well as setting up dashboards.

With our wayCloud Platform you and your partners link all relevant supply chains, processes and material flows. The wayCloud Platform does not replace your existing systems, but can communicate with them via WebAPIs if required and offers a valuable addition: a common view of the entire supply chain. This can also generate added value within your company: Information can be communicated, processes visualized and meaningful reports created.

Your data and that of your partners is stored exclusively in the Microsoft Azure Cloud on European servers in compliance with the highest security standards. Data protection is a top priority for Microsoft Cloud Services. In addition, all communications are encrypted using SSL (SHA-2 with 2048-bit RSA).

As a web-based solution, our wayCloud Platform is largely independent of the hardware you use. All you need is your PC or notebook with a common, up-to-date browser. For the automated connection of data from your ERP system, an appropriate software module can be installed (for SAP R/3 or S/4HANA, for example, a Remote Function Call (RFC) module).

6 steps for a successful go-live of your supply chain collaboration solution

The wayCloud Platform can be set up independently online within a short time. This allows you to immediately integrate first supply chain partners, upload initial data and create quick reports.

Online registration

Create your own account with your organization in a few minutes online and free of charge to a certain extent.

Create structures

Create initial supply chain structures (sites, materials, customers, suppliers, supply relations) quickly and graphically supported.

Integrate partners

Your customers and suppliers can be invited and integrated very easily via the graphical interface.

Upload transactional data

Mass-upload data (e.g., demands, stocks) or integrate them automatically via WebAPI in a next step.

Select key figures

From a number of key figures and reports, you select those that are suitable for your application field.

Collaboration and planning

Use the wayCloud Platform as SaaS solution so that it is flexible in terms of time and money for your monitoring and planning needs along the supply chain.

Test the wayCloud Platform and start with supply chain collaboration

We would like to introduce the wayCloud Platform to you personally.

Markus Schedel

Product Manager

valantic