Display and optimize business processes transparently

Process Intelligence

With valantic Process Intelligence, we enable the realization of efficiency potentials through the transparent representation of your business processes.

Display and optimize business processes transparently

With valantic Process Intelligence, we enable the realization of efficiency potentials through the transparent representation of your business processes.

Creating Sustainably Efficient and Secure Processes with Process Intelligence

In a fast-paced world, optimized business processes are of immense importance. The events of the past few months have not only presented companies with new challenges but also demonstrated the importance of ensuring the continuity of the supply chain through agile and flexible planning. Additionally, the Supply Chain Due Diligence Act, which came into effect in 2023, adds to this urgency. German companies are required to guarantee compliance with human rights and protection against health and environmental hazards throughout the entire supply chain. To ensure this, a differentiated examination of existing processes and long-term monitoring of the entire supply chain are necessary.

By efficiently utilizing existing corporate data to identify, optimize, and design IT-supported processes, companies can flexibly respond to such market changes and solidify their competitive position in the long term. With our Process Intelligence approach, we help you create transparency in your business processes and sustainably optimize them.

Better Process Design with valantic Process Intelligence

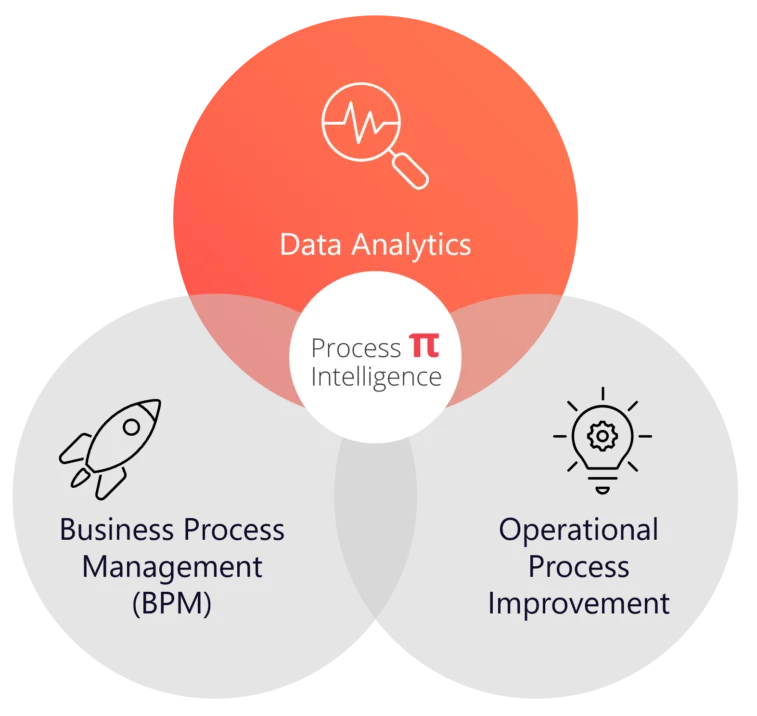

valantic Process Intelligence combines Business Process Management (BPM), Data Analytics and Operational Process Improvement to present business processes transparently and comprehensively. The interaction of Process Mining and data analysis makes a decisive contribution to uncovering bottlenecks and realizing efficiency potential.

Our Process Mining solution is based on a continuous improvement process with constant comparison of target and actual status in order to transform your company sustainably.

Data Analytics

A process analysis with process mining creates data-supported insights into your business processes and enables, among other things, the identification of deviations, bottlenecks and waste as well as their causes.

Business Process Management (BPM)

BPM is a structured approach to enhancing the efficiency, agility, and competitiveness of your business processes. We comprehensively support you in organizing your processes, thus laying the foundation for sustainable process optimization.

Operational Process Improvement

Optimize process execution based on insights gained through process automation or by using integrated IT systems to reduce manual activities and lead times.

No matter which industry, which data, which processes, Process Mining can be applied everywhere.

A large number of industries often face similar challenges. Questions arise such as: Where have been a lot of changes in sales planning? Why is an invoice not being paid on time? Where is time being lost in production?

Process Mining makes it possible to automatically reconstruct and evaluate business processes on the basis of existing data in IT systems. Process mining thus enables companies to understand how their business processes work and to manage and improve them consistently. Process Mining is not only used in different industries, but also in different departments. However, the focus is primarily on the areas of purchasing, logistics and sales.

In addition to its expertise in Process Mining, valantic has extensive industry-specific process know-how for more efficient process design.

Automotive

Mechanical Engineering

Commerce

Manufacturing Company

Telecommunications

Pharmaceutical

Insurance

Bank Sector

Process Mining as Basis for Holistic Process Modeling

Process Mining describes the automatic reconstruction of processes based on existing data from a wide variety of sources (e.g. ERP, CRM, etc.) and visualized in the form of process models or process graphs. This eliminates the need for numerous interviews and workshops. This approach enables companies to map their processes with a level of accuracy that was previously not possible.

The introduction takes place in phases, process by process and is therefore similar to several small PoCs (Proof of Concept), which are rolled out in parallel from department to department. A PoC project corresponds to the examination of a single process (e.g. order-to-cash or purchase-to-pay). In doing so, valantic combines the technical and the process view in order to map processes holistically and to identify specific weak points.

Technical View

From a technical point of view, it is the customer’s responsibility to provide the data in a certain format and quality. valantic then checks the company’s source systems (SAP, Oracle, MES system, etc.) and records points such as timestamp, object number (ID) and activity.

The above points are then consolidated and the information is passed on to the Process Mining tool. This generates the process images in all variants.

Process View

From the process perspective, valantic identifies existing silos and links them. The focus is on integration, i.e. instead of looking at individual silos, a cross-silo perspective is adopted. For this reason, not only the technical view, but also the process view is decisive for the success of the Process Mining project.

Benefit from our Know-How

Our Processes & Use Cases

The Four Core Processes

We already offer standardized, i.e. in many cases applicable and universally transferable Process Mining solutions, regardless of industry and company. This means that projects can not only be implemented more cost-effectively, but also completed more quickly.

Our „valantic Specials“

Our valantic specialties are Process Mining solutions for industry- and sector-specific processes. Thanks to our existing know-how as well as proven templates and best practices, we can offer standardized solutions that enable efficient project implementation despite a high degree of individuality.

Individualized Solutions

In addition to the cases mentioned above, there are of course also more complex, company-specific processes for which there is no standardized solution, template or use case; here we advise our customers individually and according to their needs.

Fexibility

The valantic Process Intelligence team offers comprehensive experience in the implementation of Process Mining solutions, regardless of the processes, source systems and tools.

Accelerated Process Modeling

Based on a large number of projects and experience in the context of process modeling and visualization, valantic realizes a short implementation time from data extraction to value generation.

Project Experience

The valantic Process Intelligence team has more than 8 years of experience in Process Mining, data analysis and process consulting and uses Scrum to manage large DevOps projects.

Value-added oriented

Our value proposition lies not only in the successful implementation of technologies but also focuses on generating business impact.

Training & Enablement

We are ready to train business users and IT in the utilization or implementation of Process Mining solutions. All delivered results will be thoroughly documented.

Continuous Process Improvement

We support continuous process improvements based on our process knowledge. Furthermore, we assist you in leveraging modern technologies such as RPA, workflow solutions, and AI to further automate and optimize your processes.

Yingtao Gu

Managing Consultant

valantic Management Consulting GmbH

Dominik Lehmann

Managing Consultant

valantic Management Consulting