As an implementation partner, we assist our customers with all project phases, from planning to visualization and emulation on through to start-up.

In cooperation with our technology partner for intralogistics, we also provide turnkey comprehensive solutions (steel constructions, mechanics, control technology, software) from a single source. We’ll be happy to talk to you.

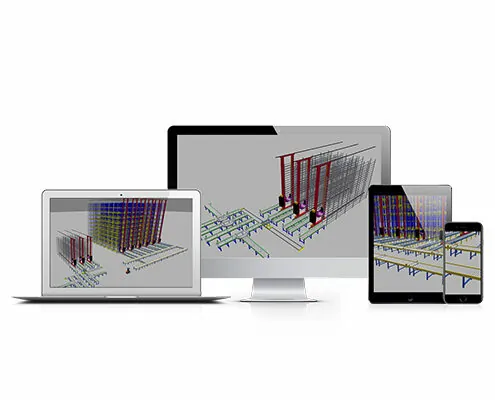

Would you like to experience your future warehouse interactively during the planning phase? No problem, with our MAGELLAN 3D planning software, we’ll create your warehouse virtually. With VR goggles and gamepad, you can access your visualizations on our web portal easily at any time from your browser and explore your future warehouse even before implementation.