Checking the status quo

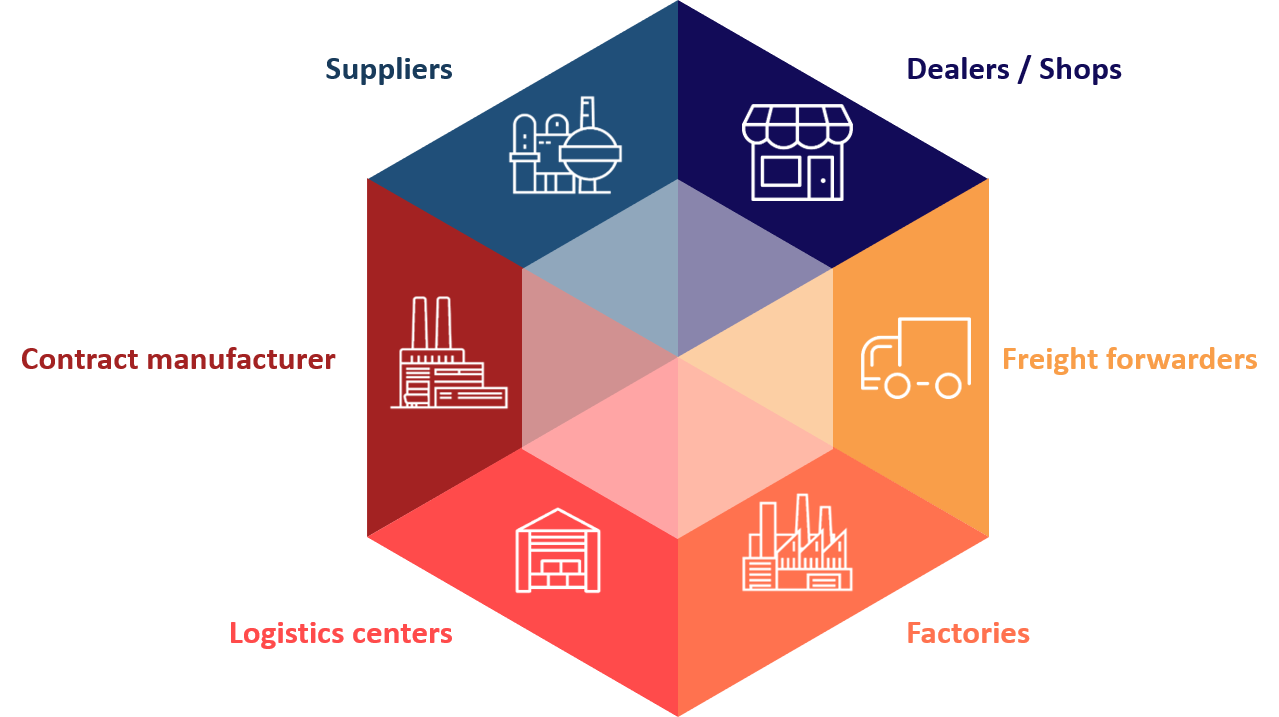

Supply chains are many companies’ backbone in today’s globalized economy. That’s why in the meantime, there is more focus on the correct design of supply chains. But even if supply chains have proven robust and resistant in the past, this doesn’t mean that they are optimally prepared for future challenges. Due to the constant, rapid growth of value chains, requirements with regard to flexibility and cost efficiency are also increasing, which can generate enormous optimization potential in established concepts.

Exploiting potential in ongoing operation

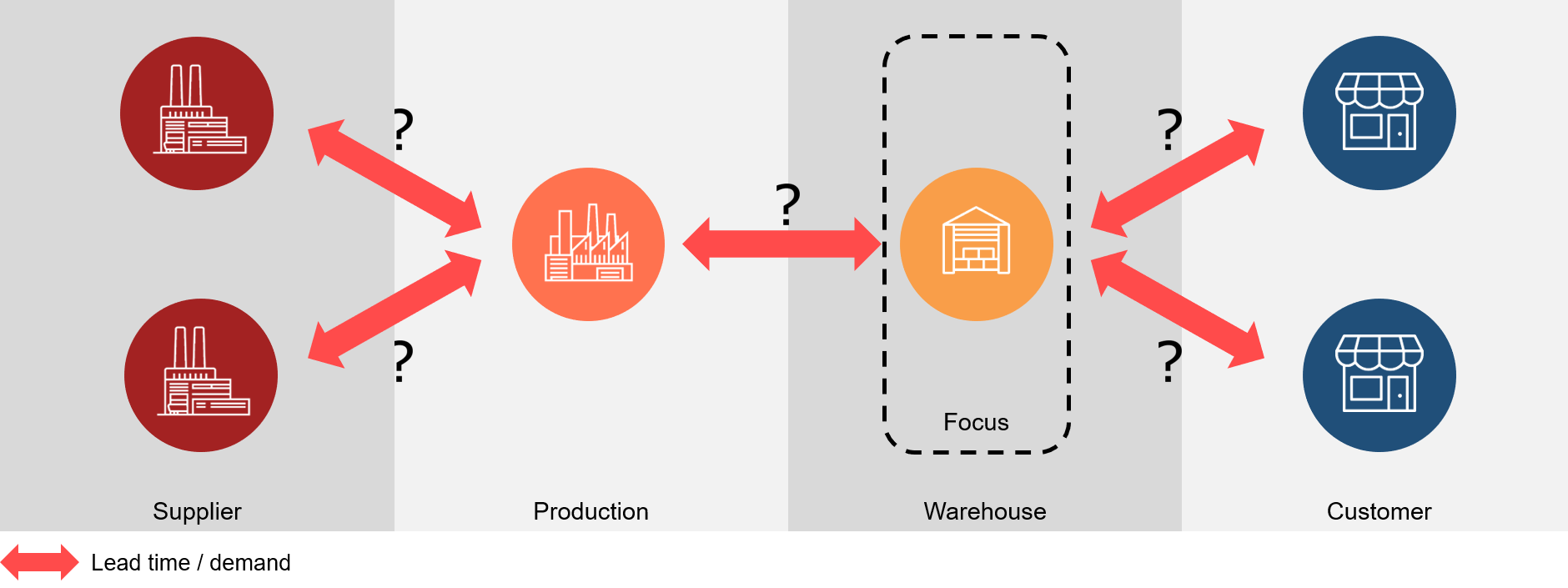

To identify this potential as quickly as possible in ongoing operation, frequently a brownfield optimization of the network will fit the bill. Here, in contrast to the complete new planning of the network (see network design greenfield), optimization potential in the existing structure is determined, evaluated, and exploited. The benefits of this procedure are on the one hand, the shorter time line and smaller amount of project work for identifying potential; on the other hand, the possibility to examine specific aspects and areas of the network individually. However, the big picture of optimizations should not be overlooked, otherwise this leads to silo thinking.

For decision-making, a comparison of the current network with various simulated variants is a good idea

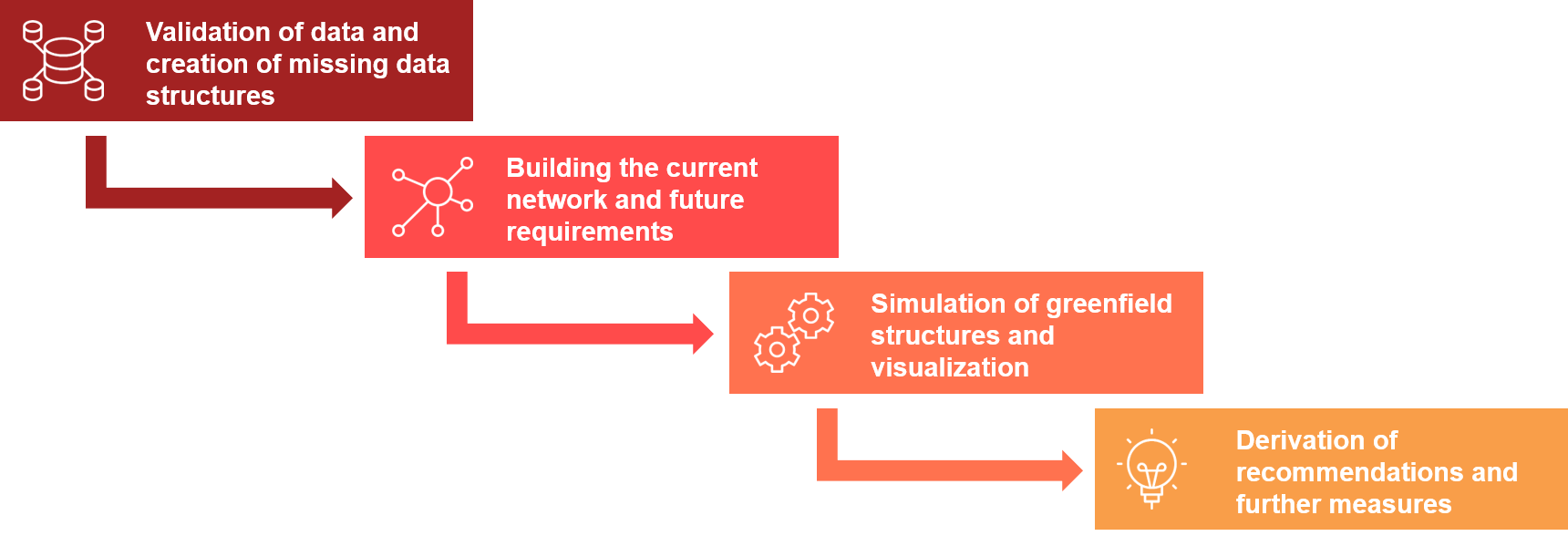

The starting point for a successful network optimization project is the recording and analysis of relevant parameters that underlie the current network. Here and there, there are gaps in the data, so that the missing data has to be defined jointly. Current supply chains can then be built based on this data structure. Thanks to the transparent revelation of all supply relationships, initial optimization potential can be identified. In addition, thanks to their many years of practical and project experience, our consultants can uncover specific improvement possibilities.

Now all applicable options in the current network can be integrated step by step as the basis for a decision-making process. Then the model runs through numerous simulation loops in order to provide a quantitative evaluation of the measures’ effects. The decision-making process is thus faster, supported, and designed objectively, which results in increased acceptance across all levels.