Transparent, optimized warehouse processes with SAP WI

SAP Warehouse Insights

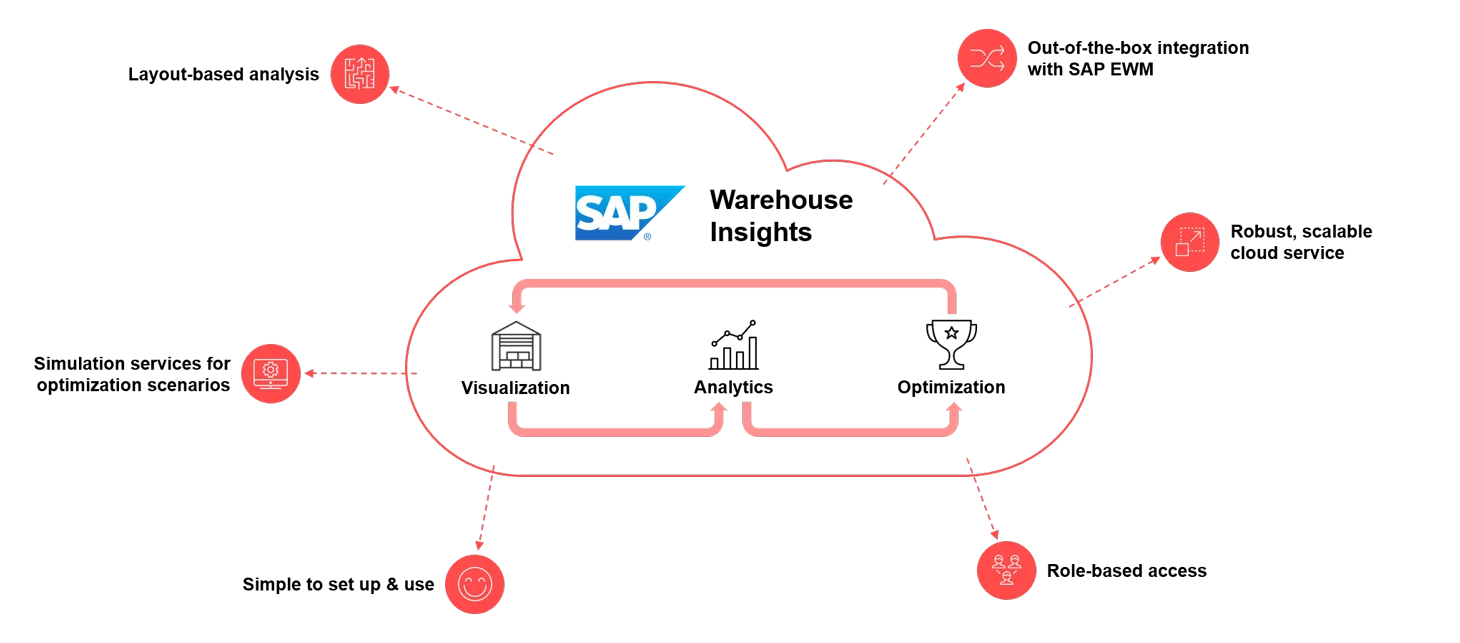

Warehouse Insights is a cloud-based SAP planning tool for the analysis, visualization, and optimization of warehouse operation in real time. Using algorithms, WI can depict the warehouse layout, calculate the relevant KPIs, simulate optimization scenarios, and monitor warehouse flows. This provides detailed insights into warehouse activities and exceptions become obvious immediately. This, in turn, provides the opportunity to intervene actively in the control of warehouse activities and therefore to optimize warehouse operation in real time.