Highlight

Successful together – our valantic Team.

Meet the people who bring passion and accountability to driving success at valantic.

Get to know usJuly 8, 2025

In a world where change has become the norm, companies are under massive pressure to make their production processes flexible and efficient. Especially in manufacturing industry, the dynamics of the market require more agile production planning.

However, the importance of fast and adaptable planning extends far beyond efficiency gains – the concern is to ensure long-term competitiveness, develop resilience to market fluctuations, and continuously increase customer satisfaction.

Agility in production planning is the key to these goals. But what does agility actually mean in this context? What technologies and methods are used? And how can companies take the first steps toward agile production? This blog post provides answers and uses practical examples to show how successful companies such as MAN, Ottobock, and BBC Cellpack have implemented agile methods.

Agility is not just a buzzword in production planning, but a strategic approach that focuses on flexibility and adaptability. Instead of pursuing long-term, rigid plans that leave little room for deviations, agile production planning relies on dynamic, data-driven adjustment of the planning in real time.

The key aspects of this approach are:

Agile production planning provides several benefits that strengthen companies in different areas:

These advantages create added value that not only increases efficiency in the short term but also ensures the company’s long-term competitiveness.

Modern technologies and methods that help companies respond flexibly to change can provide agility in production planning. With the S&OP software waySUITE, we at valantic use a number of innovative tools and strategies that make planning more dynamic and resilient – including:

Real-time data analysis and monitoring

Real-time data is the engine of agile production planning. Traditional planning systems frequently only work with today’s data; this is no longer sufficient in an ever-changing world. Real-time data enables companies to recognize current developments such as machine malfunctions, delivery delays, or unexpected demand peaks immediately and to take appropriate action.

Networked data sources (Big Data)

Agile production planning requires companies to combine data from different sources. This networking, which acts as a central “single source of truth,” provides a seamless representation of the entire value chain in real time. Data from ERP systems, supplier data, and machine data is merged and enables comprehensive monitoring and control of processes.

Automated planning processes & powerful co-pilots

Planning tools such as the waySUITE APS tool wayRTS and its digital assistants (“co-pilots”) help planning managers with routine and special tasks and free them up to make strategic decisions.

AI-based forecasting and scenario planning

Artificial intelligence and machine learning are important tools for predicting demand and production utilization. With AI-based forecasts, companies can simulate different scenarios and adapt production planning to changing conditions.

The companies MAN, Ottobock, and BBC Cellpack are pioneers in agile production planning and show how successful implementation can be:

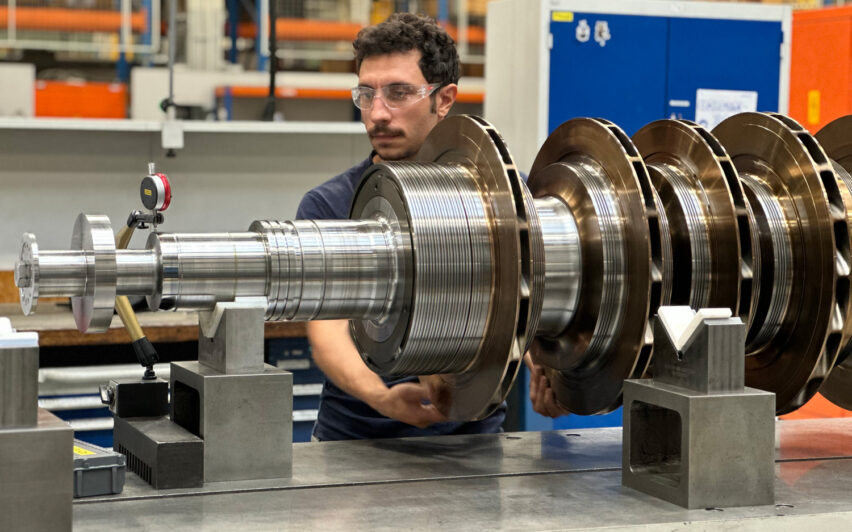

MAN Energy Solutions

With the waySUITE S&OP software suite, in particular the APS tool wayRTS, MAN is using AI-supported planning solutions to react quickly and flexibly to changes in demand.

Ottobock

This medical technology manufacturer relies on wayRTS APS software to efficiently plan its wide range of products and avoid bottlenecks.

BBC Cellpack

This specialist for high-precision finished parts has optimized its multi-plant planning with the waySUITE software suite. With real-time data and automated processes, BBC Cellpack has reduced inventories by 18%.

For companies that want to make their production planning more agile, we recommend the following first steps:

Would you like to know more about this? Arrange a non-binding consultation with us right now!

The introduction of agile production planning not only allows companies to react flexibly to changes, but also significantly increases their efficiency and productivity. In a volatile environment, agile planning is a sustainable success factor.

Real-time data, automation, and flexible planning processes are the keys to operating successfully even in dynamic times and to reacting flexibly to market requirements. Companies that rely on these methods benefit from shorter lead times, optimized resource utilization, and high customer satisfaction.

Whitepaper: Get deeper insights into and tips for agile production planning

Our “Agile production planning at the cutting edge” whitepaper offers detailed insights and practical recommendations to make your production flexible, efficient, and fit for the future.

Don't miss a thing.

Subscribe to our latest blog articles.