Highlight

Successful together – our valantic Team.

Meet the people who bring passion and accountability to driving success at valantic.

Get to know usNovember 14, 2020

According to the DIN EN 13306 standard, maintenance should preserve or restore the functional condition of an asset. It plays a vital role in ensuring the smooth operation of a company’s value-adding processes, such as mechanical goods production or reliable passenger transport through fully functional railways and trams.

Maintenance serves two main objectives: enhancing value creation and minimizing total costs. Ideally, optimized maintenance strategies achieve both goals at once.

In industrial environments, maintenance plays an important role in value creation. One of the most widely used metrics to measure this contribution is Overall Equipment Effectiveness (OEE). OEE evaluates the performance of machines and systems based on three key parameters: availability, performance, and quality.

The higher these values, the better the overall equipment effectiveness and, in turn, the greater the company’s economic success. Maintenance is instrumental in improving or sustaining high OEE levels. For example, reducing unplanned downtime directly increases availability. Other aspects, such as intelligent work order planning, also positively impact OEE.

However, OEE alone doesn’t provide the full picture. It’s essential to also assess total operating costs. Unplanned asset downtimes result in immediate financial losses, as production output falls short, or fewer passengers are transported than expected. This leads to missed revenue and profit opportunities, and, in some cases, delivery delays or service failures can even trigger contractual penalties.

Manufacturing companies face additional costs when performance or process quality is suboptimal. Even if machines and systems remain operational, they may run below their optimal speed or generate an excessive number of defects. The consequences are clear: productivity declines, while the consumption and cost of raw materials and intermediate products rise.

Inadequate product quality not only leads to direct costs through returns and complaints but also poses a reputational risk. Damaged brand trust can result in declining customer numbers and long-term revenue losses.

Ultimately, well-designed maintenance strategies help reduce the Total Cost of Ownership (TCO) of assets. Conversely, neglect or misguided maintenance decisions can drive TCO up.

To fully assess the value of maintenance solutions, their benefits must be weighed against their costs. Internally, maintenance expenses are often met with skepticism, making it all the more important to highlight potential savings.

Maintenance costs typically include:

The savings potential varies depending on a company’s specific circumstances. However, personnel and downtime costs usually offer the most room for optimization.

There are two key reasons for this:

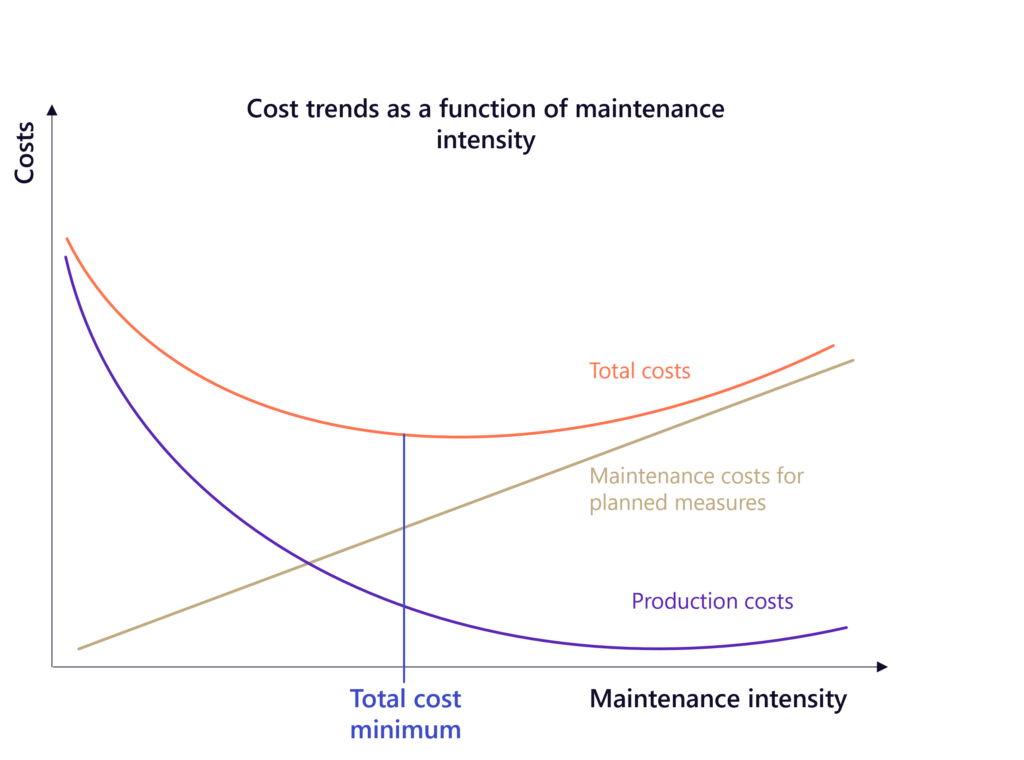

While maintenance solutions deliver significant benefits, they also come with associated costs that must be carefully evaluated. Typically, an increase in maintenance costs leads to a decrease in overall operating costs, and vice versa.

This relationship highlights the importance of finding the optimal balance between maintenance spending and total operating costs.

The diagram below perfectly illustrates the relationship.

Companies should avoid cutting maintenance costs indiscriminately, for instance, by downsizing maintenance teams or skipping essential tasks. Experience shows that such measures often backfire, leading to higher overall operating costs. A more effective approach is to implement cost-saving strategies that maintain – or even improve – maintenance quality. This can only be achieved by increasing efficiency and making optimal use of available resources.

According to our study, IT support plays a vital role here:

Mobile maintenance solutions offer substantial potential for cost savings. They allow employees to access critical information during maintenance activities, such as step-by-step instructions for specific assets, and enable real-time data capture, for instance, to document the current condition of equipment. These capabilities provide multiple advantages:

Maintenance tasks take significantly less time when employees can retrieve necessary information directly at the machine or vehicle. There’s no longer a need to search for or retrieve data afterward. This reduces both labor and downtime costs.

The benefit is particularly evident in fault diagnostics. In the event of a fault, it must be possible to answer the following questions immediately:

If this information is readily available, the root cause of the issue can be identified faster and the fault resolved more quickly.

Today, mobile devices like tablets, laptops, and smartphones are essential tools for mobile maintenance. Looking ahead, emerging technologies such as data glasses promise further efficiency gains by enabling hands-free access to digital information and supporting augmented reality (AR) scenarios.

Along with the efficiency, maintenance quality also improves, which in turn helps lower total operating costs. For instance, when maintenance procedures are clearly outlined on a mobile device and require digital confirmation upon completion, the risk of errors and inaccuracies drops significantly.

The result: longer asset uptime and fewer unexpected breakdowns.

Mobile maintenance also streamlines administrative workflows. On-site data capture and direct access to information reduce the preparation and follow-up effort surrounding maintenance tasks, cutting personnel costs. At the same time, eliminating media disruptions – such as transferring handwritten notes into digital systems – minimizes the likelihood of documentation errors.

While mobile maintenance technology is both accessible and cost-effective, many companies remain hesitant or face challenges during implementation. One possible reason lies beyond the technology itself: Despite clear benefits and readily available hardware and software, strategic success factors are often unclear. In addition, companies must address critical questions and define a clear, well-structured implementation approach tailored to their specific operational needs.

Unlocking the full potential of your maintenance strategy

How can digital resource planning and mobile applications help you get the most out of your maintenance processes? We’ve got the answers you’re looking for!

Don't miss a thing.

Subscribe to our latest blog articles.