The Collaboration Platform for Supply Chain Management

Supply Chain Transparency and Collaboration with the wayCloud Platform

The Collaboration Platform for Supply Chain Management

Better collaboration along complex, multi-tier supply chains

Planning and controlling your production with the Advanced Planning & Scheduling (APS) software wayRTS (Real Time Simulation) achieves a high degree of transparency and adherence to deadlines. However, in complex multi-tier value chains, there are factors that are not part of the company itself. Planning-relevant information from suppliers is not available in due time and must be obtained with considerable effort in some cases. It would also be desirable to keep customers up-to-date on progress and get easy feedback with no extra effort. In order to further optimize supply chain management, external partners must be involved. And that’s exactly what the wayCloud platform offers.

Incorporate customers, control suppliers

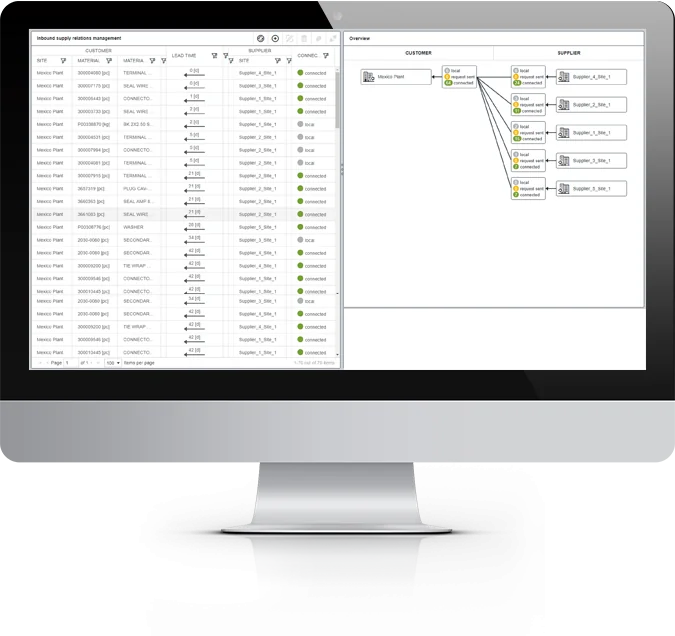

The software-as-a-service (SaaS) platform wayCloud allows you to connect as many customers and suppliers as you like with the apps tailored to the specific use cases. It provides partners with secure, precisely defined insight into their own planning results and serves as a convenient communication platform for coordination. The result: Any information is shared easily and securely with all partners involved in the process. The transparency gained this way increases the predictability of logistics processes. The wayCloud Platform Apps are ideal for demand and capacity matching, task management, communicating project and order progress, and calculating greenhouse gas emissions along the supply chain. Collaboration on the platform increases delivery reliability and delivery capability, potential supply bottlenecks can be avoided at an early stage, and emission reduction potential can be identified. The various functions can be selected and booked as individual apps. You only pay and share with your partners what you actually use.

wayCloud Platform – The Collaboration Platform for Supply Chain Management (SCM)

Include customers and manage suppliers. Read here how you can successfully collaborate along complex, multi-level supply chains with the wayCloud Platform and achieve transparency and planning security in SCM.

This graphic shows the end-2-end supply chain planning process with waySuite, as it is prevalent in mechanical and plant engineering. Especially in the medium-term planning (supply chain optimization and material supply management), close cooperation with suppliers can make a decisive contribution to the quality of the planning result.

Typical use cases

Automated integration of contract manufacturers into the value creation process

wayCloud Platform offers a simple way to integrate contract manufacturers into planning processes with the Collaboration Lists app. The integration allows the quantities, production sequence, and specific prioritization of critical orders to be transferred to the external partner without any effort. Thanks to the bi-directional communication, feedback, deviations, and changes can be communicated as quickly as possible.

Share wayPRO and Microsoft Project project plans with project partners via the cloud

In project-driven business, for example in plant engineering, there are many dependencies, because the customer must have conditions for assembly, for example. The Projects app provides a convenient way to share project plans and communicate activities and milestones.

Tasks for fine-tuning in project plans can be created and edited directly in the app according to the process steps. The wayCloud platform has a standard interface to wayPRO, but also allows a simple manual MS Project upload.

Align requirements and delivery capacities

Matching your own demand or delivery capacities with those of suppliers is a complex task. The easier it is to exchange information, the better this will go. The CCM (Connected Chain Manager) app of the way-Cloud Platform facilitates communication among partners along the multi-tier supply chain. Demand forecasts are shared and compared with actual quantities. Delivery capacity ranges, including upper and lower limits, are determined over the months. Demand fluctuations can be analyzed and warnings issued. Order promising enables easy communication of changes to orders and call-offs. Traceability of status changes and histories in the procurement process increases transparency for all parties involved. The transparency of stock ranges ensures the supply situation and increases the response time. This includes transit tracking and use of stock range KPIs to quickly identify critical materials. The graphical representation of over- and understocks facilitates the optimization of inventories. Here, valantic relies on its cooperation with Prewave, an AI (artificial intelligence) start-up that offers a global AI risk management platform. This enables risk information to be integrated and comprehensive risk monitoring and alerting to be set up.

Compiling a carbon footprint and identifying reduction potentials

The Corporate Carbon Footprint (CCF), also called climate balance, describes the sum of all direct and indirect greenhouse gas emissions of a company. With the CCF tool of the wayCloud Platform, you can calculate your carbon footprint or create your carbon footprint in an uncomplicated and standardized way in order to identify individual levers and derive suitable reduction measures. You can create your CCF in just two steps: First, record your operational activity data and then link it to emission values that you have stored yourself or that are provided by an external database. In addition to a technical solution, we are also happy to support you with expert advice on the subject of sustainability and CO2 transparency. The development of holistic measures is always in the foreground, in that we always consider economic efficiency in addition to ecological benefits.

Advantages for supply chain managers at a glance

Share views and lists from any waySuite modules and installations (cloud, on-premise) with customers and suppliers

Central communication with optional data exchange, topics requiring coordination are simply added as a "task"

Functions can be used as individual apps

Access can be controlled by roles

Encrypted communication, independently verified IT security

Browser-based user interface, access without installation; email notification

Ready-to-use right away, low usage-related costs

TISAX (L3), ISO-27001, and ISO-9001 certified vendor valantic

Microsoft Azure Hosting in Western Europe

Collaboration with the planning process in mind

The wayCloud Platform improves collaboration with suppliers and customers. The cloud service is a convenient way to clarify open questions directly using the data from the planning software and, if necessary, additional documents. Media breaks and duplicate data storage are further reduced in the interest of digital transformation.

The wayCloud Platform for highly complex statistical analyses

In addition to providing applications for collaboration, valantic leverages the flexibility and scalability of the wayCloud platform to provide additional capabilities with large computation requirements. Users can take advantage of these as needed without having to keep the corresponding IT capacities available.

DDO app (MRP data optimization / wayDDO)

With the wayDDO app provided via the wayCloud platform, the wayRTS user can exploit state-of-the-art algorithms to automate and optimize scheduling data. Historical data from the ERP as well as information from the wayRTS material master form the basis of the automatic evaluation.

wayDDO helps you

Optimize production lot sizes based on data from past periods

Perform ABC/XYZ classifications automatically

Automatically set disposition parameters based on classifications

Adjust the level and creation of security stocks

Calculate the optimum reorder level

The recording of the carbon footprint of companies and products.

The availability of the necessary data and the individual parameters are worked out during valantic’s integrated process and IT consulting. The aim is to achieve the best possible demand and inventory management.

Demand Planning app

The Demand Planning Automation app uses state-of-the-art algorithms and AI to provide forecasts for the S&OP process. A challenge for longer-term forecasting is the choice of the appropriate statistical method – wayDDO offers all currently leading technologies.

In valantic’s process and IT consulting, the appropriate calculation methods are defined jointly. From this point on, the ideal forecasting procedure is selected automatically according to the individual reference number, with the best parameterization in each case to minimize the forecast error.

Forecasts can be provided on both the primary and secondary requirements level or on the product group level. wayDDO is a fully integrated solution: The forecast requirements are made available automatically as planned requirements in wayRTS, where they form their own forecast scenarios.

What is calculated this way based on historical data in the cloud fits into an integrated S&OP process with wayRTS. This is where the automatic forecast and sales estimates are coordinated.

By using wayDDO, planners can be sure to always be up-to-date with the statistics software. They will be using the most powerful algorithms for their forecasts and automatically receive high-quality planning bases.

Stock Transparency in Critical Situations

Supply bottlenecks can be visualised immediately using the graphical web interface in valantic’s wayCloud Platform.

Overview of benefits for supply chain managers

Flexible evaluation

The efficient reporting functionality of the wayCloud Platform allows a systematic evaluation of actual and historical stock ranges of critical materials. The level of detail of the reports, the selection of materials as well as the visual design can be adjusted in a flexible way. Exporting the reports in standard formats make the sharing of information easy.

Application case: Order promising

With the order list, you can communicate orders, delivery calls, and other demands to your suppliers. They can either confirm quantities and dates or communicate new date and quantity proposals. In case of changes or confirmations, the status of the affected data records is updated and written back to your leading ERP system if necessary. This way, you make agreements via a single platform and maintain an overview at all times. Agreements that are otherwise made on the telephone or in other ways are documented centrally on the platform and can be viewed and are transparent for all participants. The order list is therefore an ideal instrument for daily cooperation between customers and suppliers.

Test the wayCloud Platform and start with supply chain collaboration

We would like to introduce the wayCloud Platform to you personally.

Markus Schedel

Markus Schedel

Product Manager, valantic Supply Chain Excellence