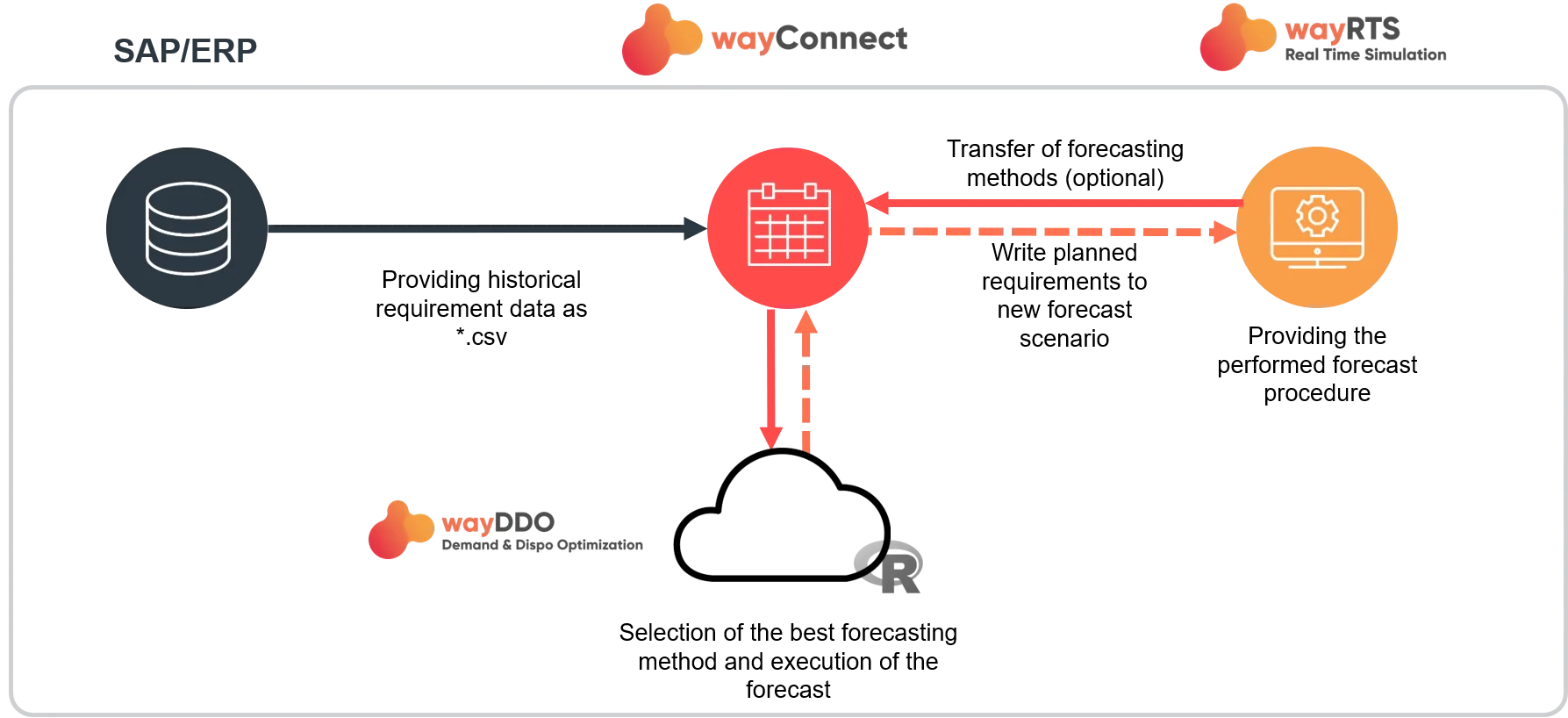

With the goal of guaranteeing precise and automated supply chain planning, wayDDO automates and optimizes the dispo data along the entire value chain: from procurement and production on through to logistics. The solution uses both historic data from the ERP system and information from the master data of the waySuite module wayRTS as input data. wayDDO automatically updates the optimized dispo data in the wayRTS material master data or generates transaction data records or adapts existing transaction data records in wayRTS.

wayDDO supports the planner with a wide variety of automation options, thus significantly reducing the planning times and work. A few examples: The tool sets production lot sizes automatically based on the average production lot sizes of the last periods. wayDDO sets, also automatically, various disposition parameters: The solution adapts the quantities of safety stocks or calculates the reorder point. Before the actual implementation, the necessary data and calculation specifications and their application are coordinated in detail.

wayDDO also handles classification of the material without a lot of time-consuming input from the planner or project planner. The ABC analysis classifies the material using the value (cumulative share of sales) and the throughput (cumulative share of demand). A-goods are the most relevant for the company.

The XYZ analysis that handles quantity control for the purchasing and storage of goods classifies the materials in their time sequences using characteristics. The relevant characteristics include the degree of demand fluctuation that is defined by the variation coefficients. X-items sell regularly and in somewhat constant quantities; the sale of Z-items, by contrast, is irregular. This results in different planning demands.

wayDDO selects dispo parameters automatically and adjusts them on a rolling basis. Reclassifications are typically done per quarter; however, they can be done at any time and without time consuming tasks. wayDDO handles the transfer automatically as proposal to the wayRTS material master. This way, the quality of the master data is improved step by step.