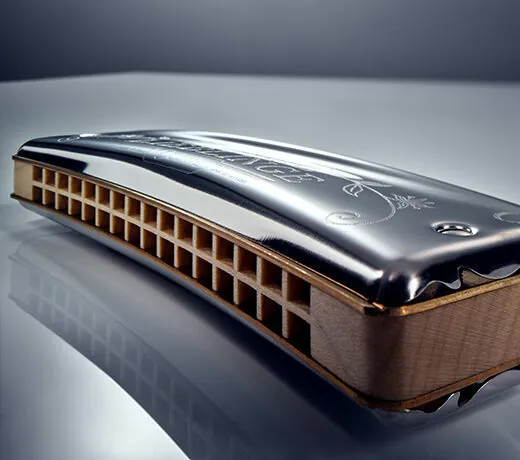

HOHNER Musikinstrumente GmbH

HOHNER and SONOR optimize Supply Chain Management

The musical instrument manufacturers Hohner Musikinstrumente GmbH and Sonor GmbH commissioned valantic with the introduction of the Advanced Planning and Scheduling (APS) solution wayRTS (Real Time Simulation). Both of these longtime manufacturers of harmonicas, percussion instruments, and Orff instruments now have much more agile, cross-plant demand and production planning with maximum transparency along the entire value-creation chain.