Hermann Waldner GmbH & Co. KG

Production Planning and Project Planning Integrated at Waldner

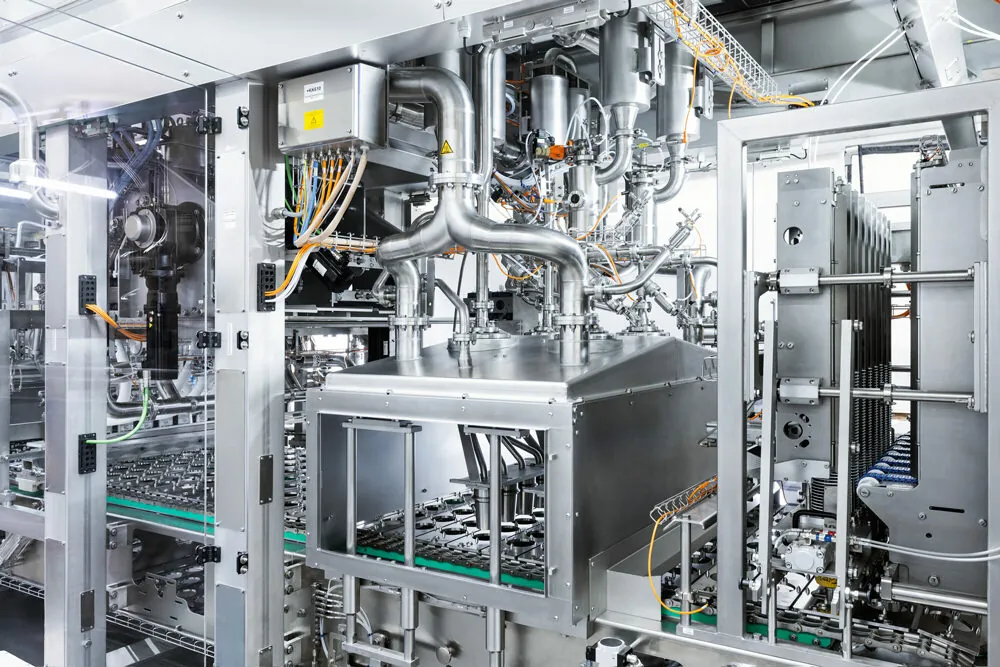

Hermann Waldner GmbH & Co. KG specializes in the production of completely automatic filling and sealing machines and the appropriate packaging systems. When the company adopted SAP S/4HANA, its planning processes were further optimized. The wayRTS APS software that Waldner is using has now been expanded to include the wayPRO component for project planning and cross-project planning transparency.