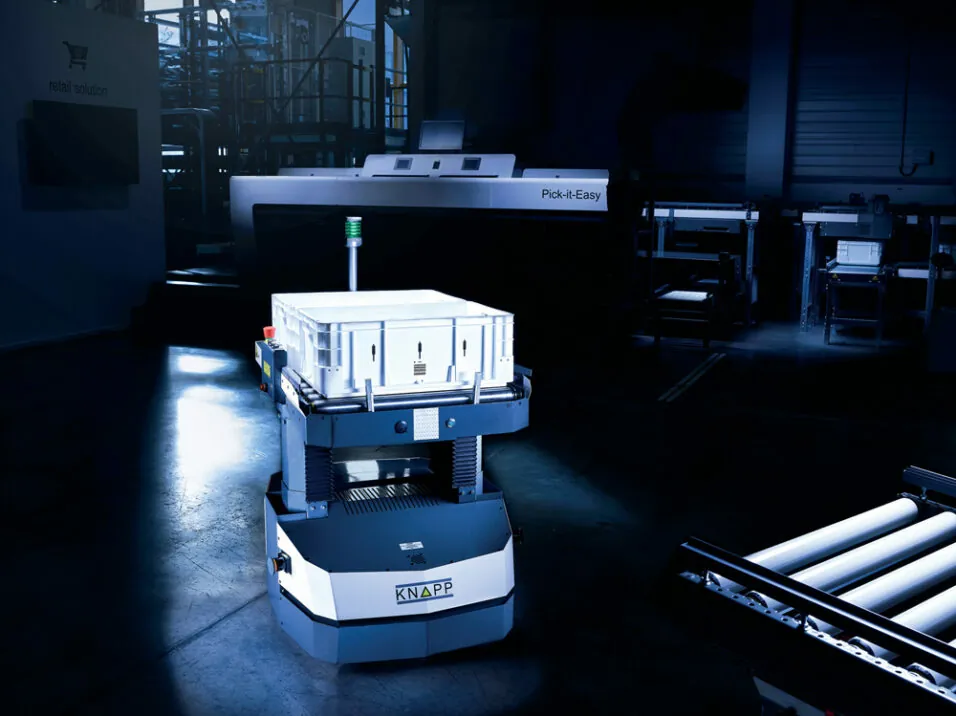

KNAPP is the technology partner for intelligent value chain management. Headquartered in Austria, the KNAPP group provides all-in-one solutions for automation and digitalization, from production and distribution to the point of sale. Excellent service and long-term collaboration make KNAPP the strong partner behind the success of their customers in the sectors healthcare, retail, food retail, fashion, wholesale and industry.

The company develops and manufactures intelligent warehouse systems using the latest solutions in digitalization, software, automation and robotics. At KNAPP, innovation, internationality and team spirit are highly valued. Worldwide, the company has about 7,000 employees, each bringing their individual backgrounds, qualifications and points of view to the table, but what unites them all is the passion they feel for their work. Providing first-class service within long-term collaborations makes KNAPP the strong partner behind the success of their customers. Their customers include the food retailer SPAR, the pharmaceutical wholesaler Herba Chemosan, the fashion brand Hugo Boss, and the e-commerce giant Zalando as well as many others.

www.knapp.com