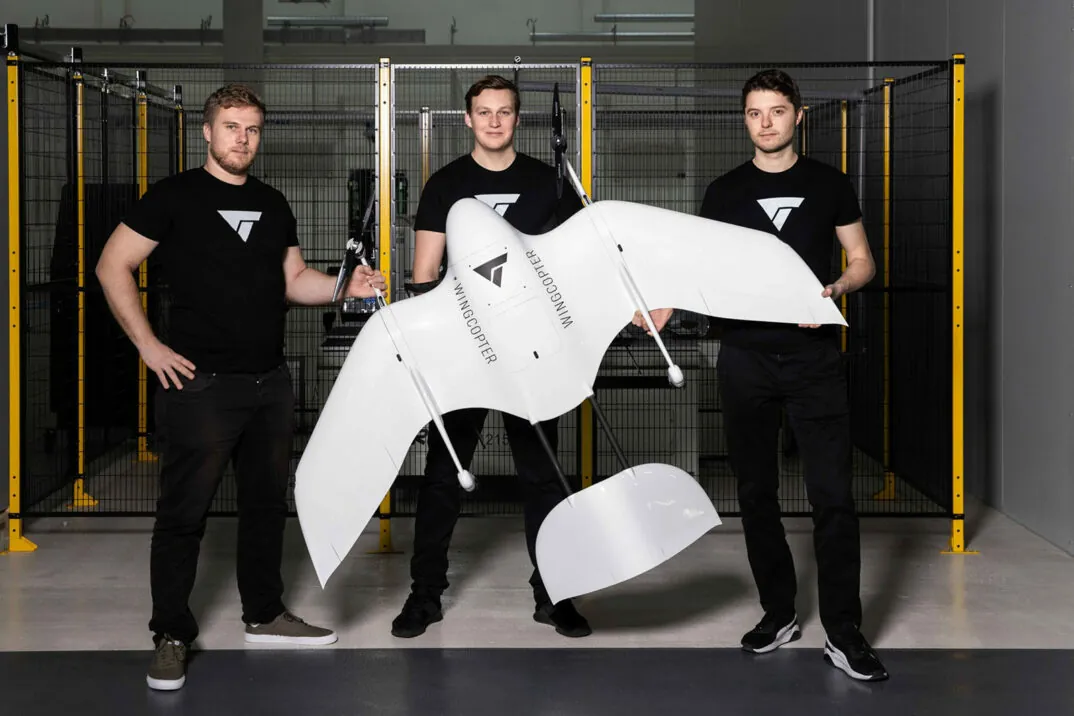

Wingcopter is a German manufacturer of electrically powered delivery drones that can take off and land vertically (so-called eVTOLs, vertical take-off and landing aircraft). This young company offers drone delivery services that, for example, optimize medical supply chains and ensure the logistics of the last mile for the delivery of urgently needed packages, tools, spare parts, and food. The vision of the 120-person team is to improve and save lives worldwide with meaningful commercial and humanitarian applications. Wingcopter is a Technology Pioneer of the World Economic Forum (WEF).

Wingcopter’s delivery drones are equipped to handle almost all weather and terrain conditions. Thanks to its patented tilt-rotor mechanism and software algorithms, the Wingcopter 198 can perform vertical take-off and landing maneuvers like a multicopter while flying long distances as efficiently and quickly as a drone equipped with rigid-fixed wings, even in rain and strong wind.

The Wingcopter 198 transports up to six kilograms of payload over a distance of up to 110 kilometers and reaches speeds of up to 110 kilometers per hour. The start-up’s investors include REWE Group, Salvia, XAI Technologies, Xplorer Capital, Futury Capital, ITOCHU, DROHNENFONDS, SYNERJET, EXPA, Hessen Kapital III, and Corecam Capital Partners.