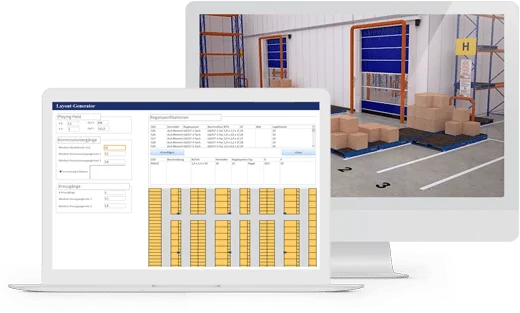

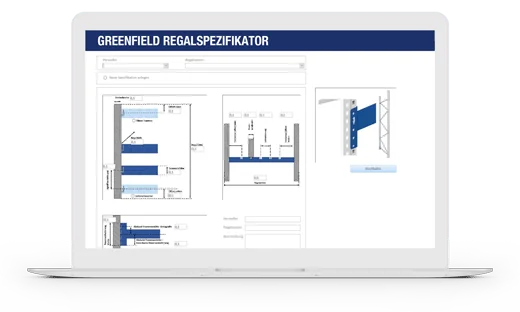

The object structure, which is based on SAP EWM and features storage types, storage areas, activity areas, transfer zones, etc., can be used to describe and logically subdivide warehousing and picking systems.

In combination with the resource management contained in MAGELLAN and the possibility of modeling any operating strategies, almost all real-life scenarios can be developed quickly and precisely.

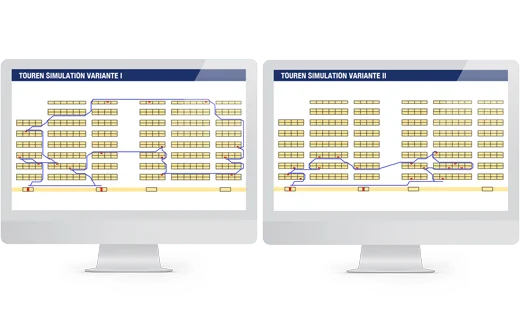

In addition, the formation and release of picking tours can be influenced by the integrated management of picking waves, order batching and stock determination. This integrative planning approach by MAGELLAN enables warehouse or picking areas to be described and effectively simulated and examined as all-encompassing systems.