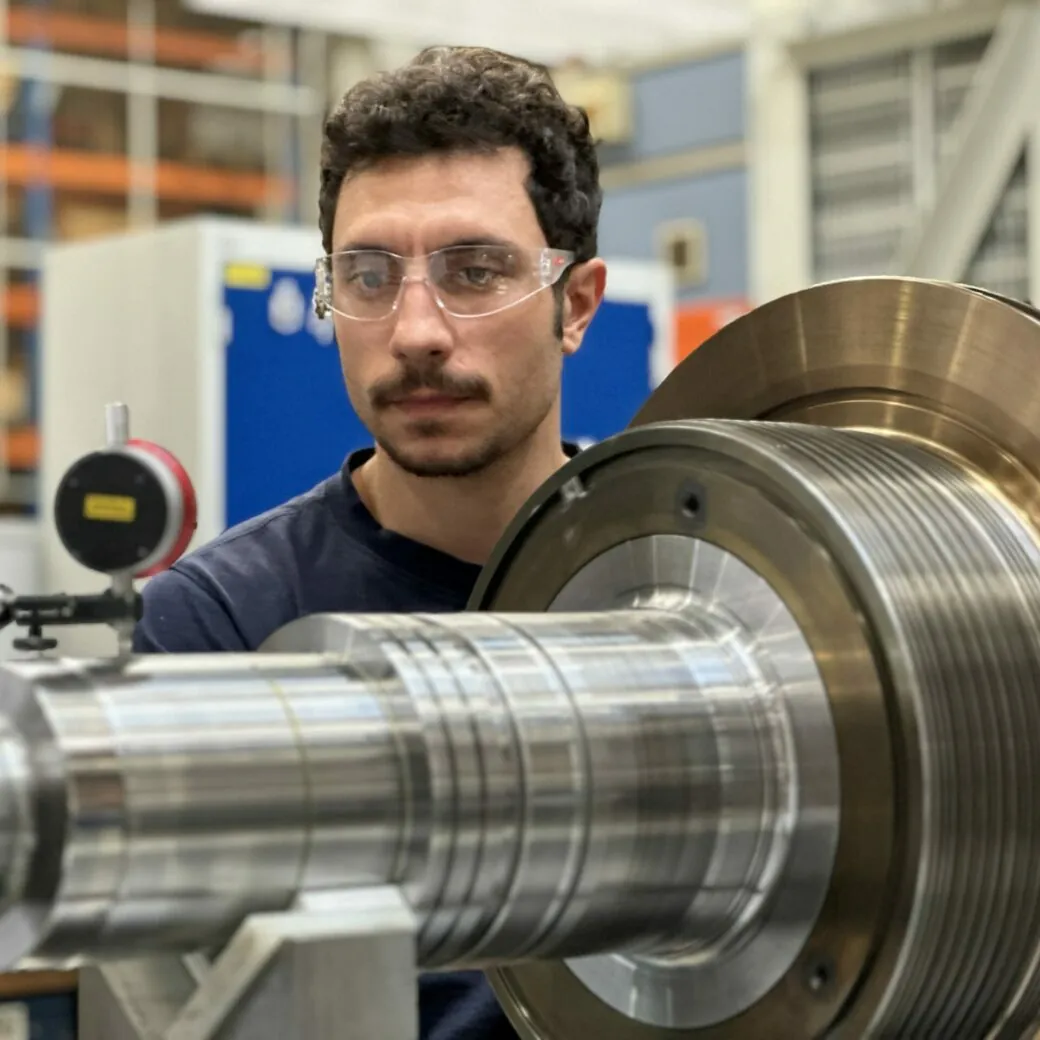

The people in charge of production and supply chain management (SCM) focus on upcoming operative planning tasks every day. These include operative procurement and disposition, production planning, and the scheduling of new customer orders. Here, many decisions have to be made each day, so it’s important to keep an eye on the short-term planning horizon as well.

Within sales & operations planning (S&OP), the people in charge plan once a month or sometimes for a longer period of time. On the one hand, this affects demand planning, with which the best possible forecasts of future sales are identified. In a second step, APS realtime tool wayRTS checks the feasibility of these sales figures and orients the entire supply chain according to them. Based on this information, strategic decisions can be made for long-term production planning and control:

Another central task of supply chain management is project planning, including project management of complex and long-running projects in order to coordinate all involved departments as well as possible. Comprehensive planning thus includes all relevant value-creating processes, from development to sales. An essential success factor for efficient S&OP or advanced planning & scheduling system (APS) such as valantic’s waySuite is the continuous monitoring of supply chain performance through a suitable KPI system and key performance indicator (KPI) tool.

The planning results should be reflected in real time in order to provide the people in charge with the best possible information at all times and guarantee optimal production control.

The efficient and fast communication of planning system and ERP/SAP systems is an essential guarantee of the great transparency and up-to-dateness of planning and master data. waySuite supports the planning situations described thanks to integrative software modules with a standardized interface between the ERP/SAP system and waySuite. This is how waySuite helps users with all planning tasks along the company’s supply chain.

Benefits for your processes