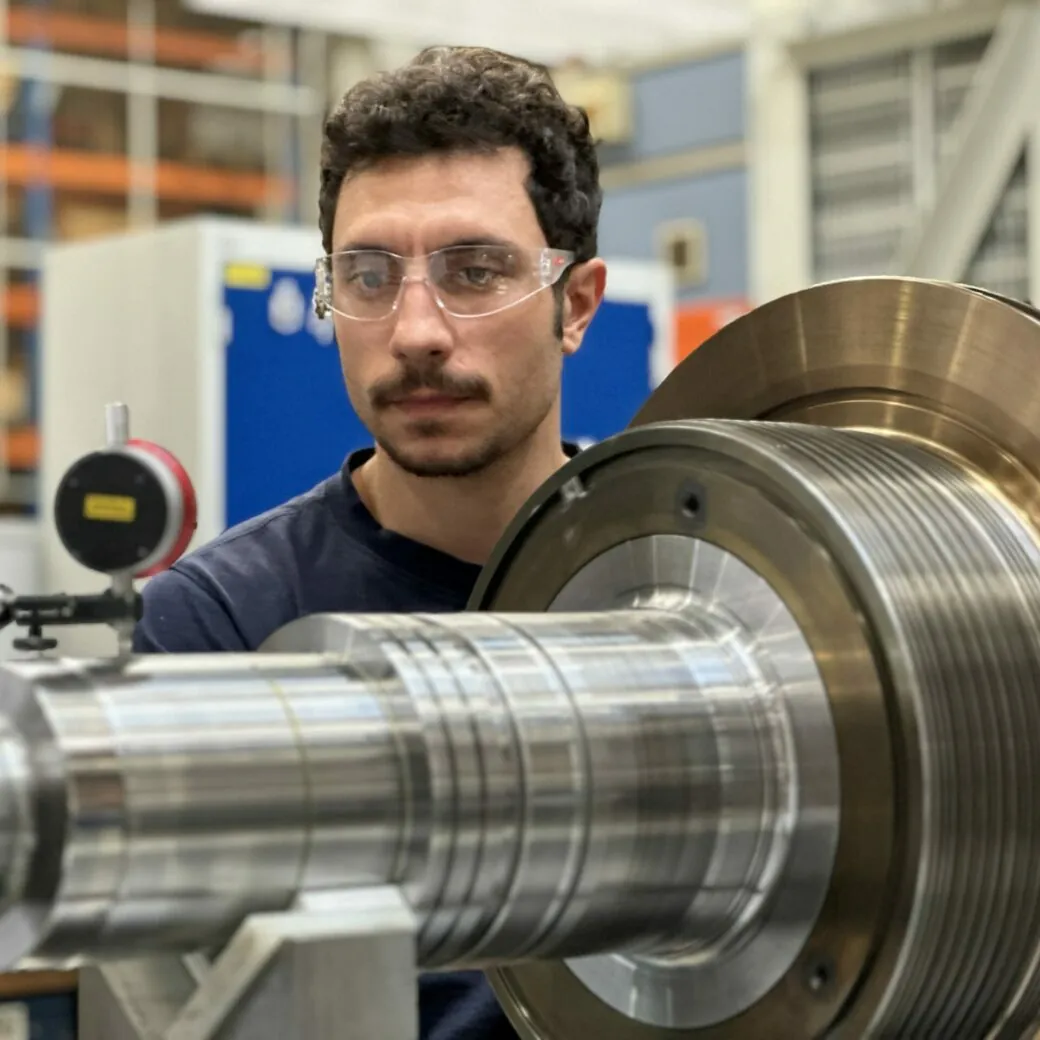

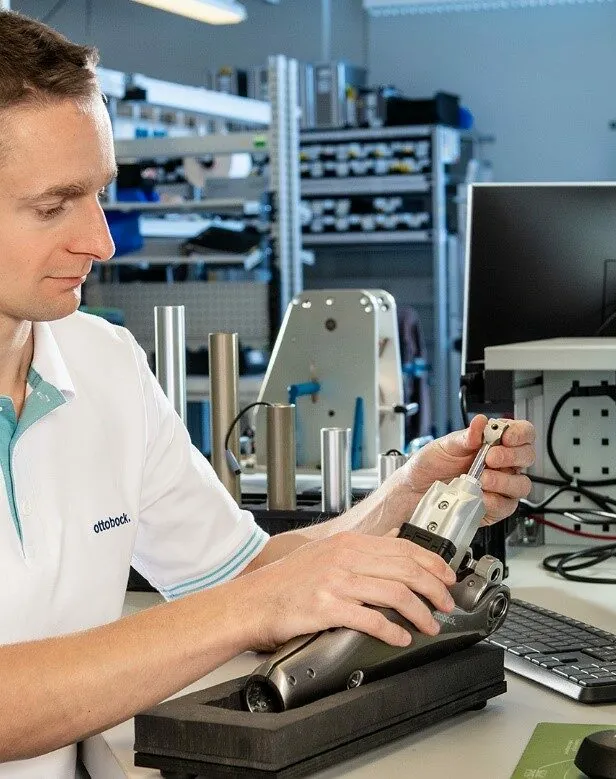

The high-performance realtime APS (advanced planning & scheduling) software wayRTS (Real Time Simulation) assists companies with production planning and control of all value-creation levels. With wayRTS, planning becomes transparent, which allows users to make simple interventions with automatic planning support.

The modeling of production processes and seamless integration and synchronization of other value-creating processes such as in the pre-production phase (design, planning, work preparation) are possible thanks to the flexible, main memory-based data structure of wayRTS. And all this in real time.

The same data structure is used for rough and fine planning, which means that breaks between different planning levels are a thing of the past. This is how wayRTS creates the ideal prerequisite for exploiting business potential in the supply chain: great adherence to schedules and productivity with market-appropriate throughput times and optimal inventories.